OVERVIEW In dry pet food manufacturing, the standard palatant application sequence typically follows three steps: (i) fat spraying, (ii) liquid palatant spraying, (iii) dry palatant application. Most fats must be heated (30-40 °C) to remain liquid. Once the fat is applied, palatants are usually layered on top, as depicted in...

An Approach to Customizing Palatants: Spray Drying

What is spray drying?

The impact of technology plays an essential role in developing a successful palatant. Spray drying is a process technology that has widespread use in various industries from human food to pharmaceuticals. It is also used in the pet food industry and is one of the technologies AFB International uses to create palatants.

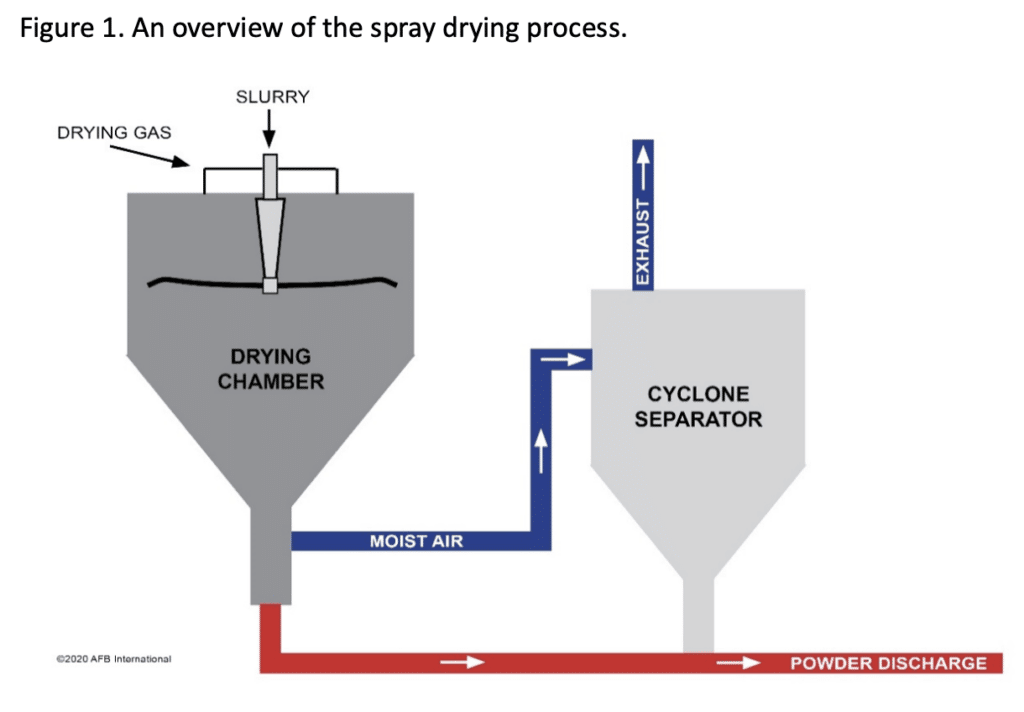

Spray drying is one of the many ways to microencapsulate an ingredient – usually via a carrier. The benefits of microencapsulation include improved ingredient stability, prevention of degradation and extending shelf life. Depending on the spray drying equipment, the liquid slurry can be composed of a solvent or water. The slurry is fed through the nozzle at the top of the dryer and the drying gas is injected into the chamber. Then, due to the temperature difference, the water (or a solvent) is removed as it falls through the drying chamber. The moist air moves from the drying chamber to the cyclone via the drying gas and the powder produced is discharged. (Figure 1.)

Benefits of a spray dried palatant

Spray drying allows AFB to easily transform a liquid mix into a powder. Dry powder palatants provide customers with transportation savings and ease in product handling. Spray drying is a faster, more efficient technology for easier scale up in production, translating to quicker delivery times to the customer. Additional benefits include shelf stable ingredients, halting reactions between components, and minimizing flavor loss over time. Spray drying also allows for particle size, flow, and moisture control depending on the formulation.

AFB International Research and Development

www.afbinternational.com