OVERVIEW In dry pet food manufacturing, the standard palatant application sequence typically follows three steps: (i) fat spraying, (ii) liquid palatant spraying, (iii) dry palatant application. Most fats must be heated (30-40 °C) to remain liquid. Once the fat is applied, palatants are usually layered on top, as depicted in...

Ensuring coating consistency: challenges and approaches

Several factors such as fat level, application rate, and coating systems affect uniform coating of palatants.

This study focused on evaluating the coating consistency of palatants applied to kibble. Coating consistency is defined as the uniform application of the palatant on the kibble, leading to better product performance.

Electronic tongue, surface pH, sodium meter, Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) were the methods used to determine the coating levels of the palatants. Using a combination of methods helped determine the expected versus actual adherence of the palatant.

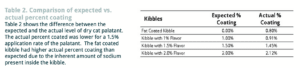

Kibbles were coated with 3% fat and various levels of dry cat palatant (1%, 1.5%, and 2%) to establish the calibration curve. All samples were analyzed using electronic tongue, surface pH meter, sodium meter, and ICP-MS to estimate the percent coating of the dry cat palatant on the kibble.

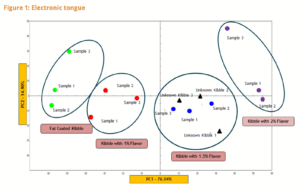

The electronic tongue classified the kibbles into groups based on the application levels of the palatants (Figure 1). The Principle Component Analysis (PCA) showed a 76.04% (PC1) classification between the kibbles, and the unknown kibble was predicted to belong to kibble cluster with 1.5% flavor.

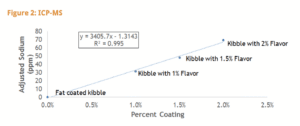

The calibration curve provided an R2 of 0.995 at various levels of dry cat palatants coated on the kibble. This calibration curve was used to determine the actual amount of palatant adherence in an unknown sample.

SUMMARY

Electronic tongue is an excellent qualitative tool to provide insight into coating consistency. The unknown kibble was predicted correctly to belong to 1.5% adherence rate cluster. This method cannot provide the exact percent coated or adhered.

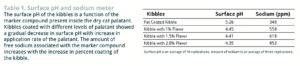

Surface pH – good indicator of similarity or difference between different percent coating, but not in predicting the exact percent coated or adhered.

Sodium meter provides the quantitative amount of sodium associated with the marker compound, but is subject to variability with a standard deviation of +50 and has limitations with the detection range.

ICP-MS is an excellent quantitative tool to estimate the exact amount of sodium associated with the marker compound, and is able to estimate the exact percent coated or adhered on the kibble derived from the calibration curve.

To learn more about palatant coating consistency, contact your sales representative or visit afbinternational.com/contact