OVERVIEW Palatants are flavor enhancers, that are applied in pet foods to improve their inherent palatability and increase acceptability. They can take various forms, such as liquids or powders, and are typically coated onto dry kibble or added within the chunk or gravy of wet pet foods. Palatants designed for...

Delayed Dry Palatant Coating: Does it affect palatant recovery rate and palatability?

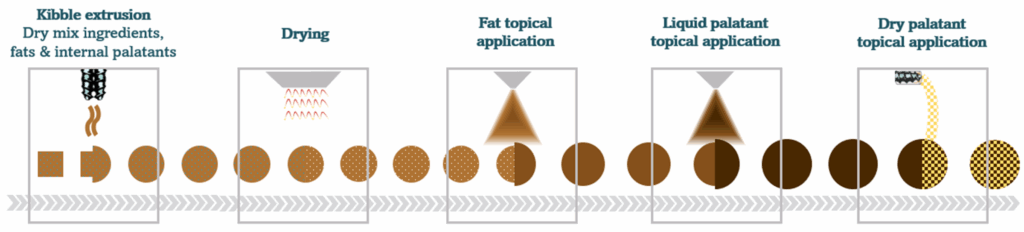

In dry pet food manufacturing, the standard palatant application sequence typically follows three steps: (i) fat spraying, (ii) liquid palatant spraying, (iii) dry palatant application. Most fats must be heated (30-40 °C) to remain liquid. Once the fat is applied, palatants are usually layered on top, as depicted in Figure 1.

However, in certain situations, such as when the dry palatant is applied at a different location, it may be necessary to coat pre-fat-coated kibbles with dry palatants at a later stage.

This study investigates two key questions:

• Does applying dry palatant on room-temperature fat-precoated kibbles reduce palatant adhesion efficiency?

• Does this delayed application affect palatability?

Figure 1: Simplified representation of the palatants application in dry pet food.

EXPERIMENTAL DESIGN

Three coating conditions were tested:

• Direct dry palatant application: 3 % of fat was sprayed onto 3 % fat-precoated kibbles. The 3 % fat-precoated kibbles were produced in a standard way, with the fat being sprayed on warm dried kibbles exiting the dryer.There was a three-week interval between the two fat applications, and the latter was followed by an immediate dry palatant application.

• Delayed dry palatant application #1 (3 weeks delay): 6 % of fat was sprayed onto uncoated kibbles. After three weeks of storage, the dry palatant was applied.

• Delayed dry palatant application #2 (3 months delay): Same as Condition 2, but with a three-month storage period before applying the dry palatant.

Each condition was tested on both cat and dog kibbles, using dry palatant application levels of 1.5 % and 2.0 %.

The same poultry fat (applied at 35 °C) was used across all conditions.

Measurements

• Recovery Rate (RR): using analytical tracers, the actual percentage of dry palatant recovered on the kibbles was calculated.

• Palatability testing:

• carried out in AFB dog and cat kennels with 30 animals over two days;

• versus tests were analyzed using paired t-tests for dependent samples.

• Moisture content: controlled to ensure it did not influence palatability results (cat: 5.8 % ± 0.1, dog: 7.0 % ± 0.1).

• Crude fat content: verified for coating uniformity (cat: 11.9 % ± 0.3, dog: 10.4 % ± 0.3).

RESULTS

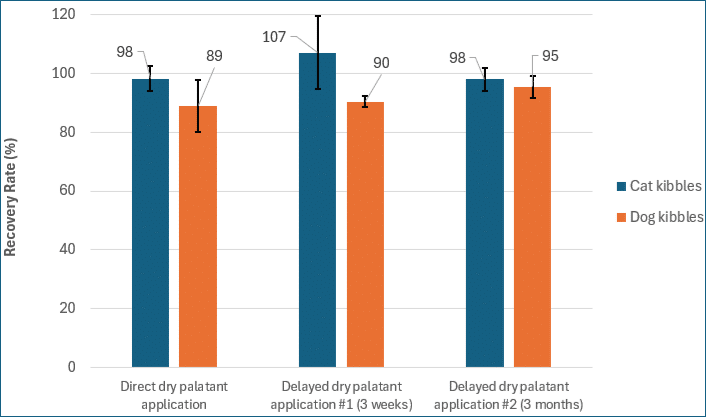

Recovery Rate of dry palatant

• Figure 2 illustrates the RR of the dry palatant for each condition.

• Key finding: the RR remained consistent across all conditions, indicating that at this fat level (6 %) dry palatant.

Figure 2: Recovery Rate of dry palatant under different coating conditions.

Recovery Rate of dry palatant under different coating conditions.

Palatability results

• Table 1 summarizes the results of the versus tests.

• Key observations:

• the tests showed no statistically significant difference in palatability.

• one case showed a significant preference: cat kibbles with 1.5 % dry palatant, applied after 3 weeks.

Table 1: Palatability test results for differential dry palatant coating (versus test, n = 30 animals).

CONCLUSION

• Delaying dry palatant application does not reduce adhesion efficiency.

• Palatability remains unchanged, except in one specific case.

These findings indicate that dry palatant application can be delayed by days, weeks, or even months after fat coating without compromising product performance or dry palatant adhesion.

This flexibility could be particularly useful when:

• applying dry palatants in a separate coating line (e.g., liquids in a batch coater, powders in a continuous coater).

• manufacturing two diets that differ only in the coating step.

• conducting trials in AFB facilities using customer-specific fat and application conditions.

Cautionary note: These results are based on a limited set of conditions (one type of fat, one type of kibbles, one dosage of fat…) and should not be taken as universally representative. They are intended to provide insights rather than conclusive evidence.

To learn more about this topic or to speak with our Science & Technology experts, please contact your AFB Sales representative or visit afbinternational.com/contact.

White Papers:

- Delayed Dry Palatant Coating: Does it affect palatant recovery rate and palatability?

- RECUBRIMIENTO SECO DE PALATANTES CON APLICACIÓN TARDÍA: ¿INFLUYE EN LA TASA DE RECUPERACIÓN Y LA PALATABILIDAD?

- RECOBRIMENTO SECO DE PALATABILIZANTES COM APLICAÇÃO TARDIA: INFLUENCIA A TAXA DE RECUPERAÇÃO E A PALATABILIDADE?