CUSTOMER TECHNICAL INSIGHTS, AFB INTERNATIONAL Overview Moisture content (MC) in dry pet food is often underestimated. Manufacturers typically associate it with mold risk, overlooking its impact on palatability. While the link between MC and kibble palatability is generally acknowledged, it remains rarely quantified, leaving many questions unanswered. This study provides...

Leveraging Moisture to Improve Dry Pet Food: Cost Efficiency

CUSTOMER TECHNICAL INSIGHTS, AFB INTERNATIONAL

Overview

Parts I and II of this whitepaper explored how moisture content (MC) influences both palatability and quality in dry pet food.

While cost optimization typically focuses on formulation, moisture management is often overlooked.

This Part III examines how MC can impact cost efficiency, with quantitative insights and practical explanations.

Drying Energy Cost

While drier kibbles tend to enhance palatability for cats, removing water (a nearly free ingredient) comes at a cost. Over-drying not only reduces yield but also increases energy consumption.

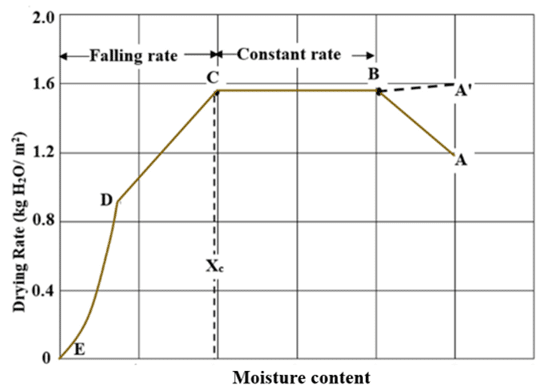

In Figure 1, drying starts at point A’: kibbles enter the dryer already hot from extrusion (unlike point A, where products would start drying from a lower temperature). Drying progresses at a relatively steady rate as free water is efficiently removed, until the critical moisture (point Xc). Beyond Xc, only tightly bound water remains. Evaporating it requires significantly more energy, and the process enters the falling-rate phase. Pushing MC even lower causes a sharper decline in drying rate (point D), shifting from early to late falling-rate phase. This results in disproportionately high energy costs for minimal moisture reduction.

Conversely, wetter kibbles improve palatability for dogs, and reduced drying leads to significant savings.

Figure 1. Drying rate vs. MC (adapted from Khan et al., 2022).

Case Study

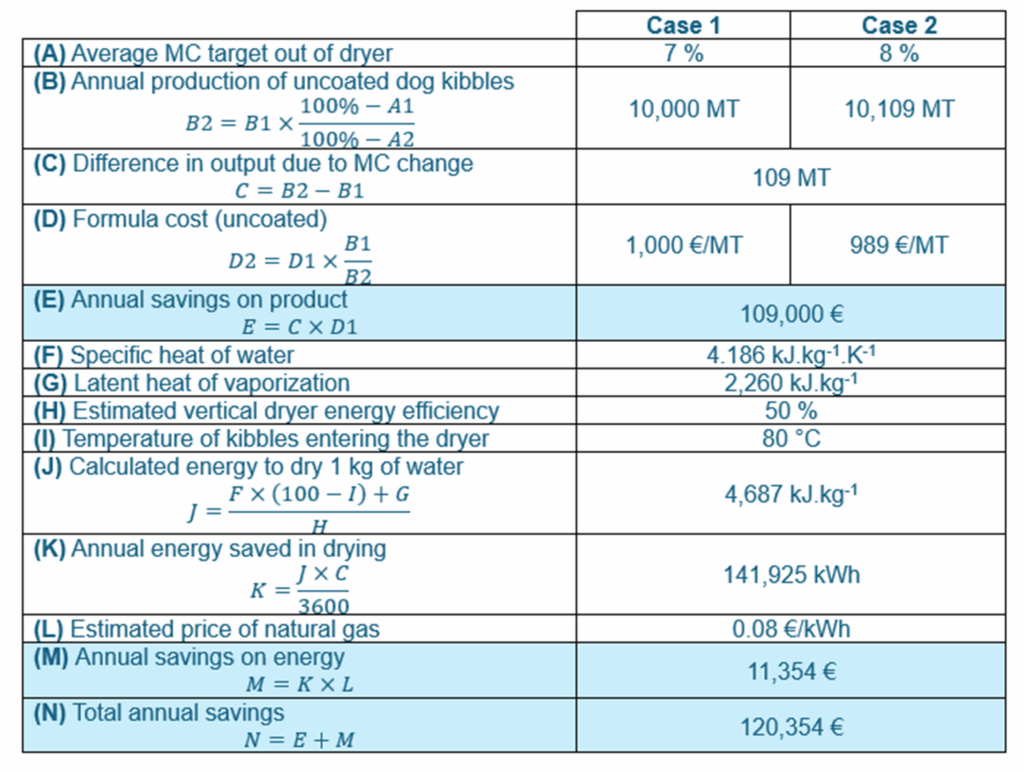

Table 1 highlights the strong potential of MC optimization in dry dog food. In this example, for every unit of currency saved on energy, nine are saved through improved product yield (a 1:9 ratio). Such ratios are common and may shift slightly depending on context: toward energy savings when energy prices are high (e.g. in certain countries), or toward product yield when formula costs are elevated (e.g. super premium diets).

Table 1. Case study: annual savings potential when increasing drying target from 7 % to 8 % MC in 10,000 MT of uncoated dry dog food. All calculations are based on dry matter. Moisture increase results in higher output and reduced cost per MT.

Conclusions & Discussion

Parts I and II of this whitepaper demonstrated how managing MC enhances palatability and quality in dry cat and dog food.

This Part III focused on a third key aspect of MC optimization: its economic impact. For dry cat food, lower MC improves palatability but increases costs: finding the sweet spot is key.

For dry dog food, the goal is to push MC as high as technically feasible to combine great palatability and cost savings, while maintaining MC low and stable enough to ensure product quality.

To learn more about this topic, or to speak with our Customer Technical Insights experts, please reach out to your AFB Sales representative or afbinternational.com/contact.